Static Analysis

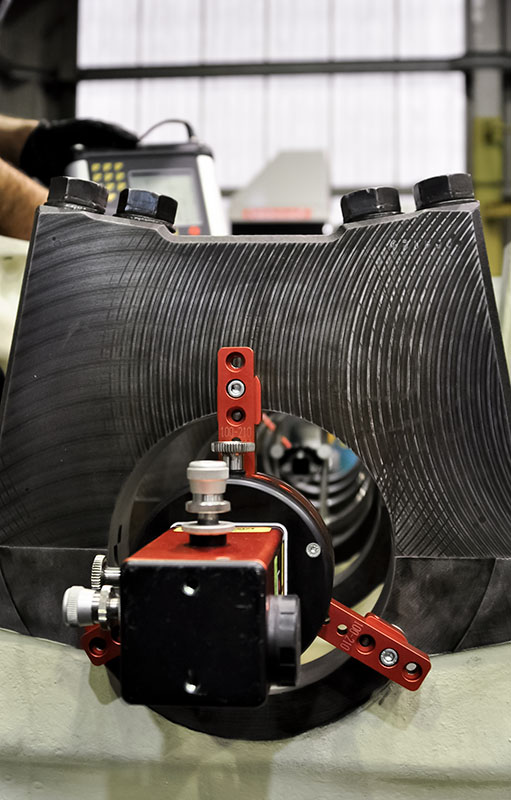

LASER LINE-UP

Alignment through laser technology has meant an important implementation in the proper arrangement of combined equipment, alignments, component measurement, flatness establishment…

In comparison to dial gauges, laser technology improves measurement precision, removing the problem of axial or radial deflection due to the supports employed for the placement of the dials and the corresponding error in the measurement, as well as allowing measurements to be taken on equipment installed more efficiently and with less execution time.

COTERENA is currently specialised in four main types of alignment:

- Linear alignment (horizontal/vertical) between equipment.

- Bedplate support concentricity

- Shaft line alignment

- Establishment of machined surface flatness

JACKLOAD TEST

The propulsion shaft alignment tests by preload (jackload test) involve a high-precision calibration of all the existing support points between the propeller horn and its connection to the propulsion system gearbox.

COTERENA has been working for years with shipyards, taking measurements according to the specifications of propeller manufacturers and according to the criteria of rational alignment, developing specific equipment for recording the measurements resulting from this alignment system.